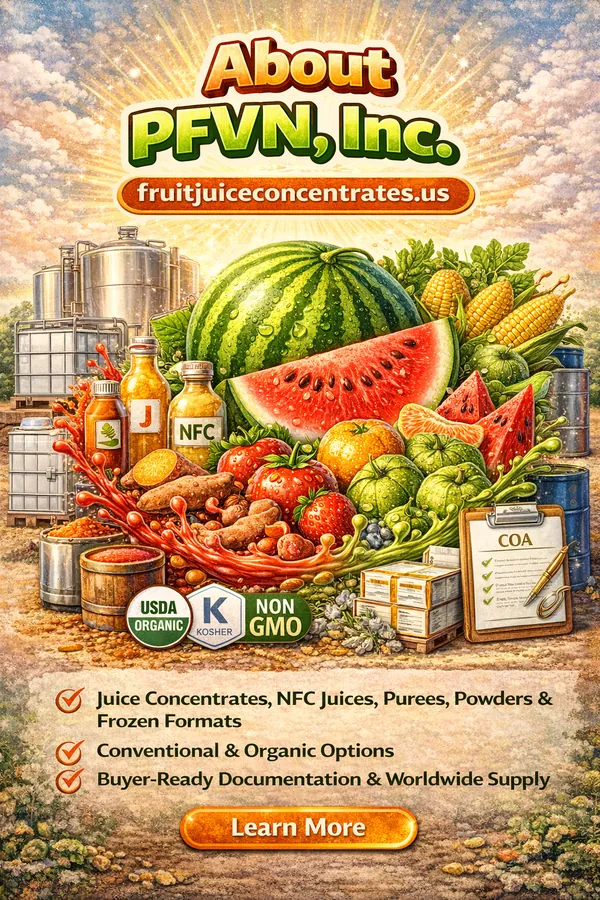

About PFVN, Inc.

PFVN, Inc. supports manufacturers and brand owners with bulk fruit & vegetable ingredient sourcing for beverages, dairy, bakery, confectionery, and culinary applications. We help your team procure juice concentrates, NFC juices (not-from-concentrate), purees, powders, and frozen formats by matching your target spec, packaging, documentation needs, and realistic lead times.

If you are replacing an ingredient, launching a new SKU, or qualifying a second source, we focus on “buyer-ready” clarity—so procurement, QA, and R&D can align quickly on what matters: °Brix, acidity/pH, color, flavor profile, microbiology, certifications, and logistics lane.

Looking for a specific fruit or vegetable? Start at Products to see typical formats by item (concentrate, NFC, puree, powder, frozen).

Fastest way to quote: tell us the item + format, target °Brix (for concentrates), pH/acidity range, packaging (drums/totes/aseptic/frozen), estimated volume, destination, and timeline.